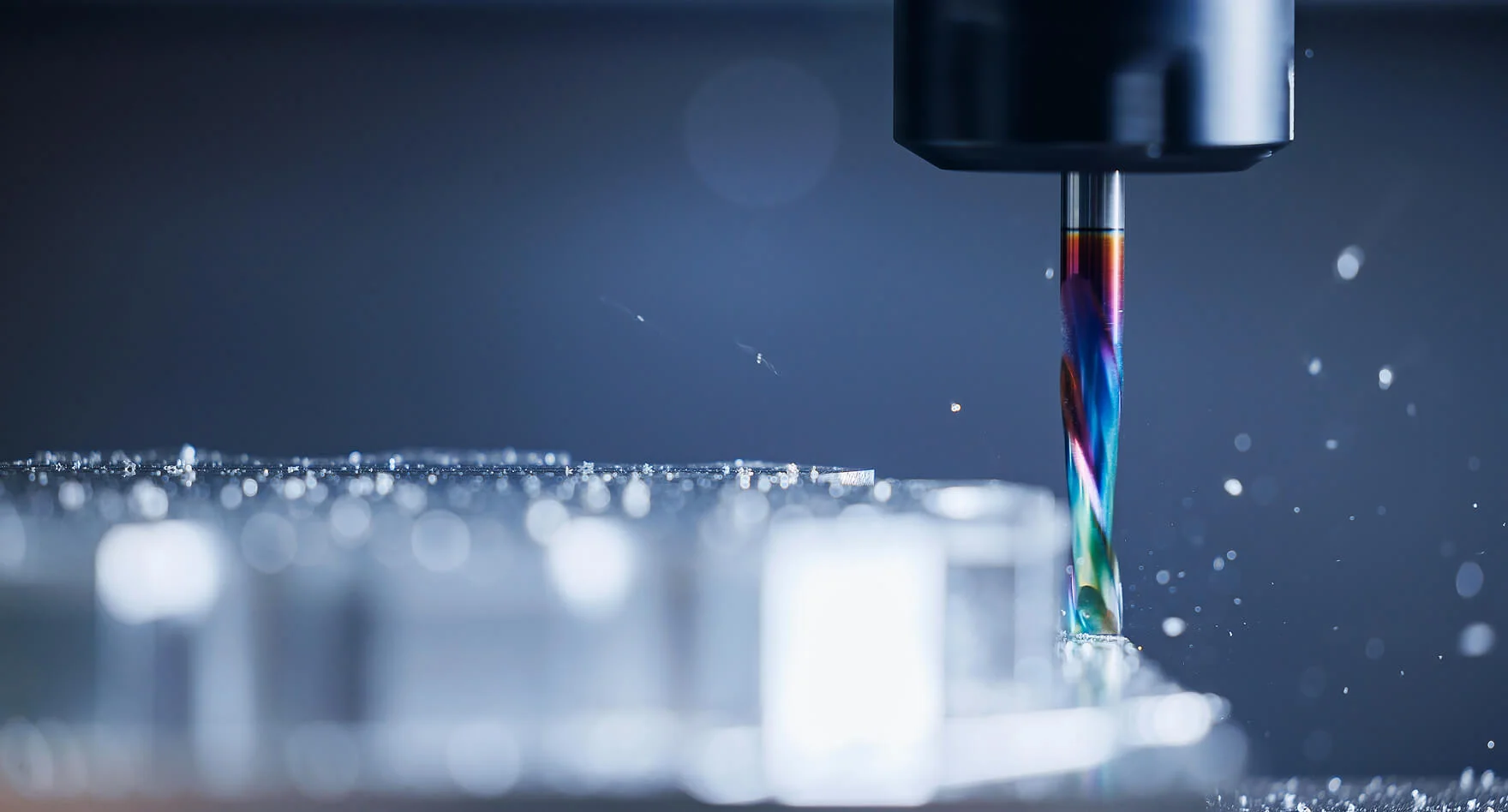

Every MicroLineTM part begins as a precise engineering model, transforming from CAD to finished product with zero compromise along the way. This process embodies what Miltech does best—merging design intent with real-world performance to create components that stand up to pressure, vibration, and time.

RYERTEX* G-10 Composite Top Resists Fretting, Heat, and Corrision. (MIL-SPEC 19177-GEE) 65,000 psi compressive strength, 55,000 psi tensile strength

Custom-engineered for Your Equipment Specifications Crafted for strength, reliability, and seamless integration into your operation

Two-piece Adjustable Chock System Built with stainless steel shims for long-term accuracy and easy realignment when needed

Steel Base Construction Provides superior strength and durability for demanding environments

The MicroLineTM family covers the critical components that keep heavy machinery precise and protected. Each part is machined to exacting tolerances, ensuring lasting performance under constant load and motion.

Maintain perfect alignment for compressors and diesel engines, even under extreme vibration.

Measure and maintain bolt tension to prevent costly failures before they happen.

Deliver a stable, level foundation for high-output engines and rotating equipment.

Secure large machinery in place, absorbing stress to protect your most critical systems.

Every MicroLineTM part is crafted under Miltech’s AS9100-certified quality system—the same rigorous standards trusted by aerospace and defense manufacturers. It’s how we ensure reliability, repeatability, and performance in every piece we produce.